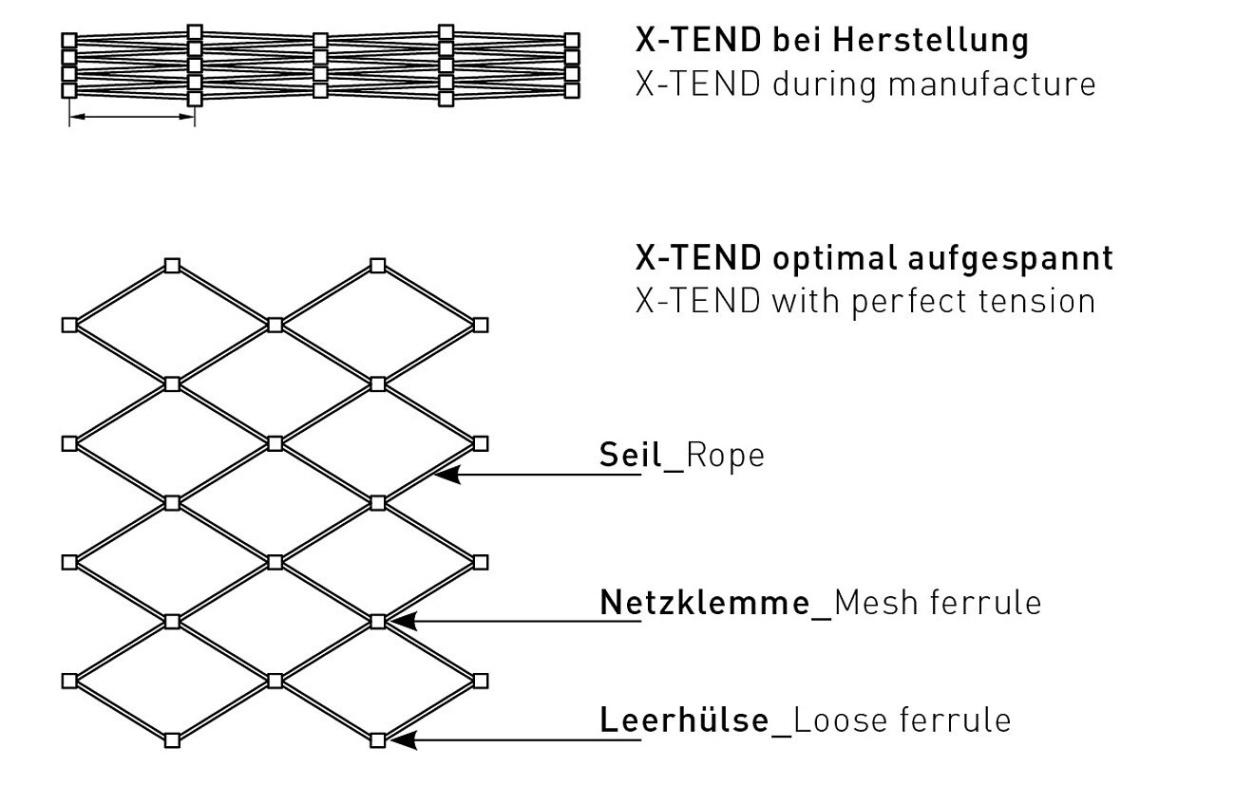

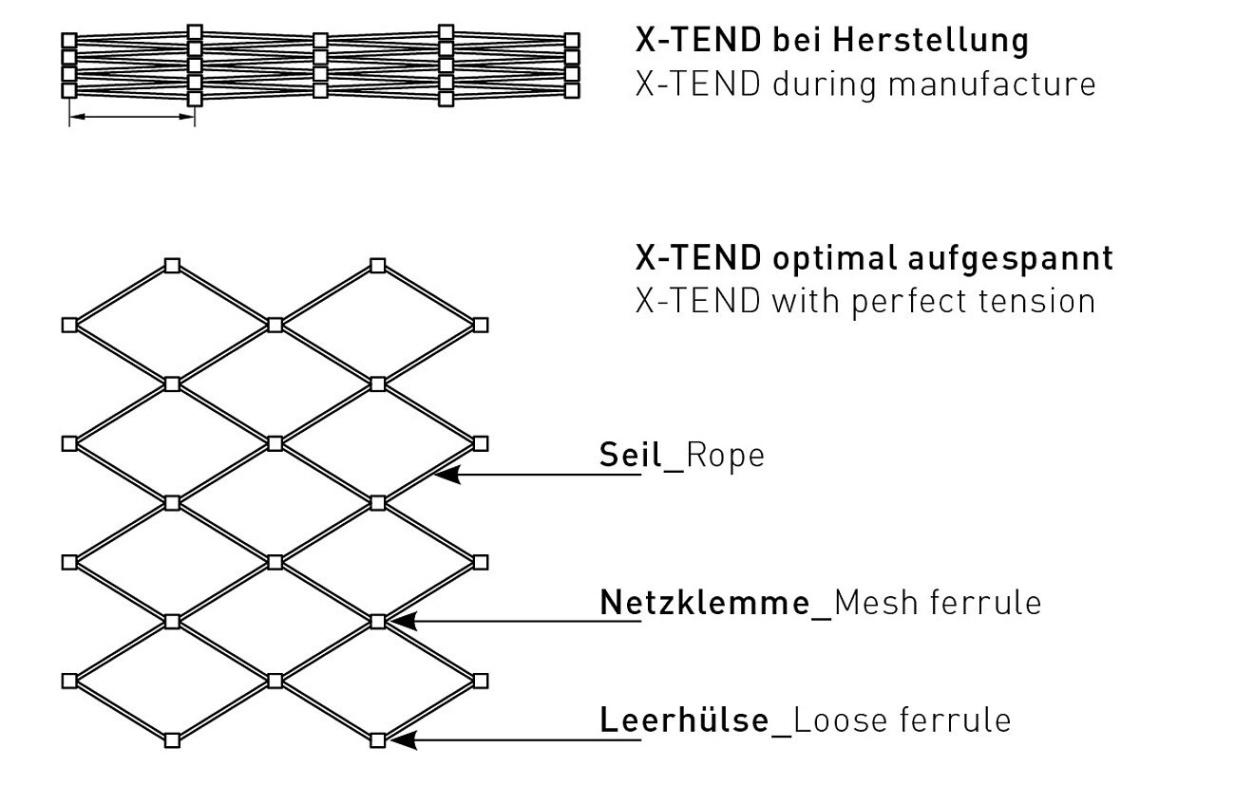

Stainless steel cable netting, also called X-TEND mesh/Webnet, is manufactured from robust, high-grade DIN 1.4401/AISI 316 stainless steel cables. The cables are swaged with tinned copper (type CX) or stainless steel (types CXE and CXS) clamps in a special process to form a mesh structure that is both stressable and flexible and suited for either two- or three-dimensional applications. X-TEND keeps its shape indefinitely and stands for long lasting use.

| Availability: | |

|---|---|

| Quantity: | |

Joysun

73144900

Stainless steel cable netting, also called X-TEND mesh/Webnet, is manufactured from robust, high-grade DIN 1.4401/AISI 316 stainless steel cables. The cables are swaged with tinned copper (type CX) or stainless steel (types CXE and CXS) clamps in a special process to form a mesh structure that is both stressable and flexible and suited for either two- or three-dimensional applications. X-TEND keeps its shape indefinitely and stands for long lasting use.

X-TEND is fabricated from high-quality and robust stainless steel cables (material: AISI316). These are linked together by a special method using stainless steel ferrules to form a stressable yet flexible structure for two- or three-dimensional applications. X-TEND keeps its shape indefinitely and requires little maintenance only during its long lifetime.

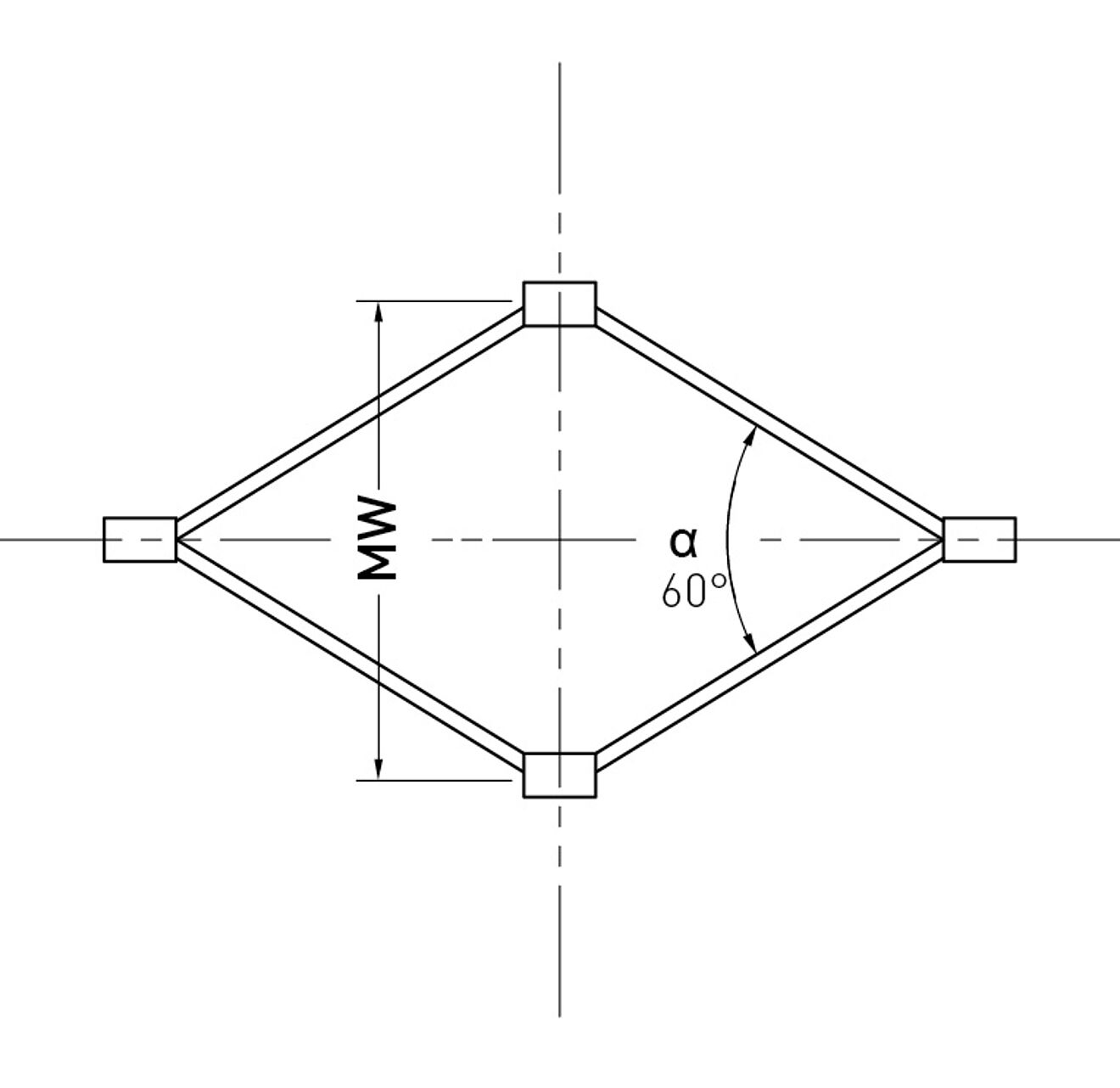

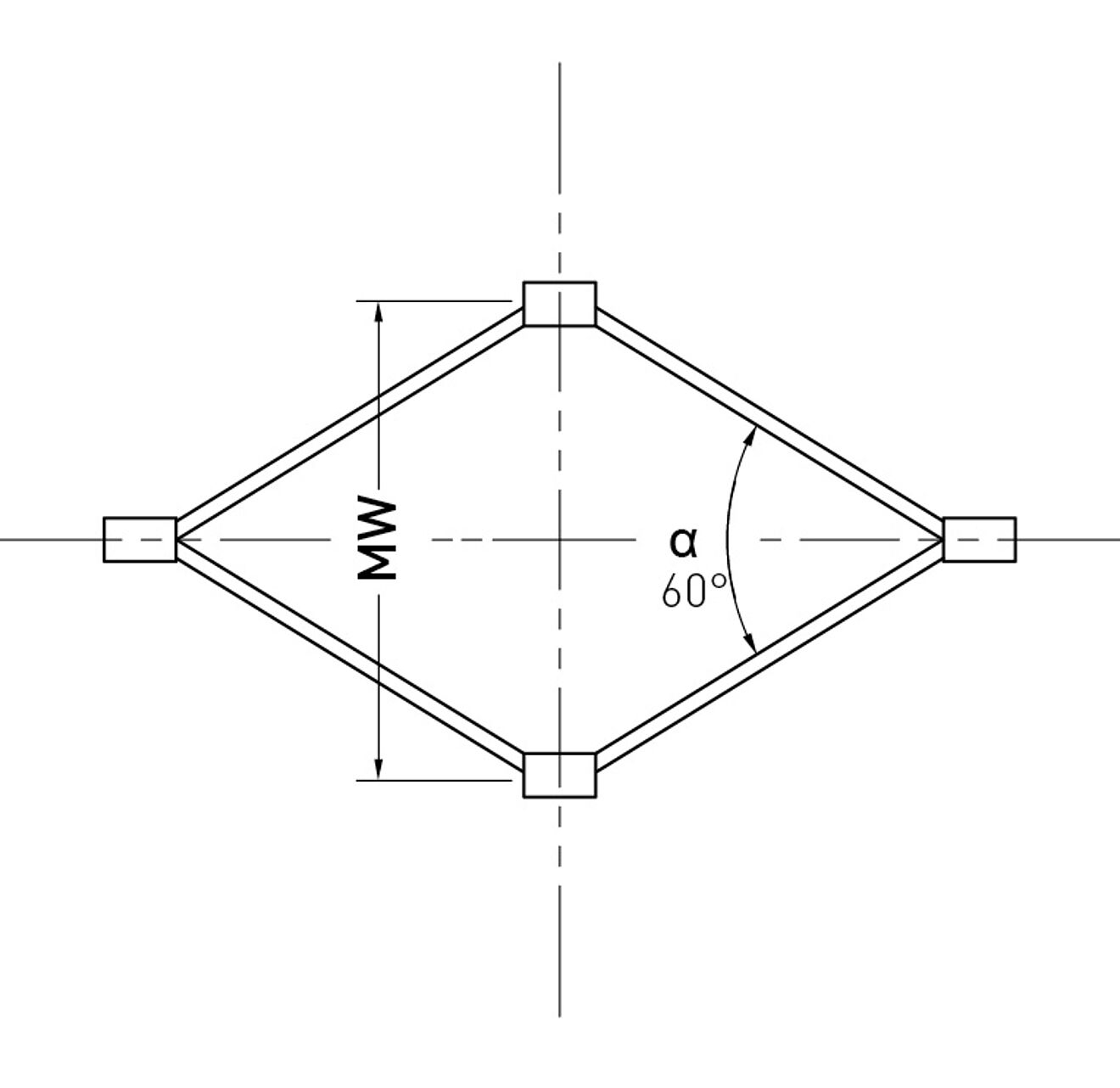

Mesh geometry

The mesh width (MW) refers to the distance from the centre of one ferrule to the centre of the next ferrule. The optimal mesh geometry with an opening angle of 60° is given when the mesh width and the distance between the ferrules’ centres along the mesh's cables

are equal. This results in the ideal tension of the mesh and is the mathematical basis for the quantity take-off.

MW Mesh width (distance from center to center of ferrule) α Standard mesh opening 60 °

Ferrule

Ferrule is a classic. It is versatile, flexible and economical, especially with small rope diameters. The sleeves are made in a specially developed process in our factory by skilled workers. Webnet with sleeves is a good choice for all projects where design and cost-efficiency are of prime importance.

Knotted

Knotted net is even more transparent than the version with sleeves while delivering practically identical strength values. Moreover, there are no troublesome light reflections from the sleeves. Consequently, sleeveless Webnet is ideally suited for strong and unobtrusive protective nets as well as for animal enclosures in zoo applications because it is easier to see through it when viewing the animals.

Stainless steel cable netting, also called X-TEND mesh/Webnet, is manufactured from robust, high-grade DIN 1.4401/AISI 316 stainless steel cables. The cables are swaged with tinned copper (type CX) or stainless steel (types CXE and CXS) clamps in a special process to form a mesh structure that is both stressable and flexible and suited for either two- or three-dimensional applications. X-TEND keeps its shape indefinitely and stands for long lasting use.

X-TEND is fabricated from high-quality and robust stainless steel cables (material: AISI316). These are linked together by a special method using stainless steel ferrules to form a stressable yet flexible structure for two- or three-dimensional applications. X-TEND keeps its shape indefinitely and requires little maintenance only during its long lifetime.

Mesh geometry

The mesh width (MW) refers to the distance from the centre of one ferrule to the centre of the next ferrule. The optimal mesh geometry with an opening angle of 60° is given when the mesh width and the distance between the ferrules’ centres along the mesh's cables

are equal. This results in the ideal tension of the mesh and is the mathematical basis for the quantity take-off.

MW Mesh width (distance from center to center of ferrule) α Standard mesh opening 60 °

Ferrule

Ferrule is a classic. It is versatile, flexible and economical, especially with small rope diameters. The sleeves are made in a specially developed process in our factory by skilled workers. Webnet with sleeves is a good choice for all projects where design and cost-efficiency are of prime importance.

Knotted

Knotted net is even more transparent than the version with sleeves while delivering practically identical strength values. Moreover, there are no troublesome light reflections from the sleeves. Consequently, sleeveless Webnet is ideally suited for strong and unobtrusive protective nets as well as for animal enclosures in zoo applications because it is easier to see through it when viewing the animals.

Article: The Importance of Fall Protection Safety Nets in Modern ConstructionBuilding Safety Starts from the Top — Literally.In construction, industrial maintenance, and high-elevation work environments, safety is not just a requirement — it is a responsibility. Every year, falls from height remain

Introduction to Tank-Intercepting MeshThe tank-intercepting mesh is a powerful defense tool designed to immobilize heavy vehicles like tanks. It is made from sturdy iron wires woven into a mesh structure that can be easily deployed across open fields or roads.Invisible DefenseOne of the unique featu

This article highlights the versatile applications of stainless steel drop safety nets across various industries. These safety nets play a crucial role in enhancing workplace safety by preventing falls and protecting workers, equipment, and the public. Key applications include construction sites, industrial facilities, warehouses, public spaces, marine and offshore environments, agriculture, and mining. The article emphasizes the durability, strength, and reliability of these nets, making them essential safety measures in diverse settings. For more information, readers are encouraged to visit the company's website or contact their sales team.

What is the Advantage of the Stainless Steel Wire Rope Net?In various industries, from architecture to marine applications, stainless steel wire rope nets have become a preferred choice due to their exceptional properties and versatility. Here, we explore the advantages that make stainless steel wir